Basic Info.

Model NO.

MY1200

Computerized

Computerized

Automatic Grade

Automatic

Application

Paper Packaging Materials

Non-Stop

Feeding and Deliverying

Transport Package

Pallet

Specification

ISO9001, CE

Trademark

Juxing

Origin

China

HS Code

84414000

Production Capacity

10set/Month

Product Description

MY SERIES

Besides the sensors at die-cutting part, there are sensor or approach switches at window part to make the whole machine at monitoring status to ensure its safety.

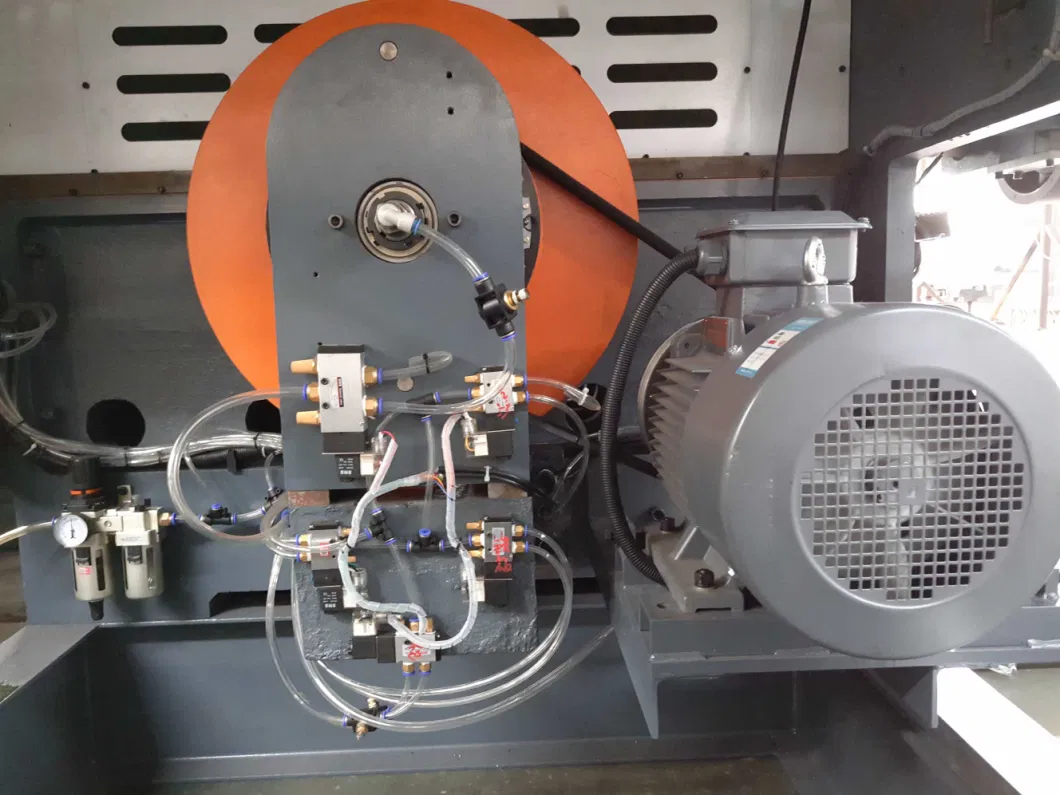

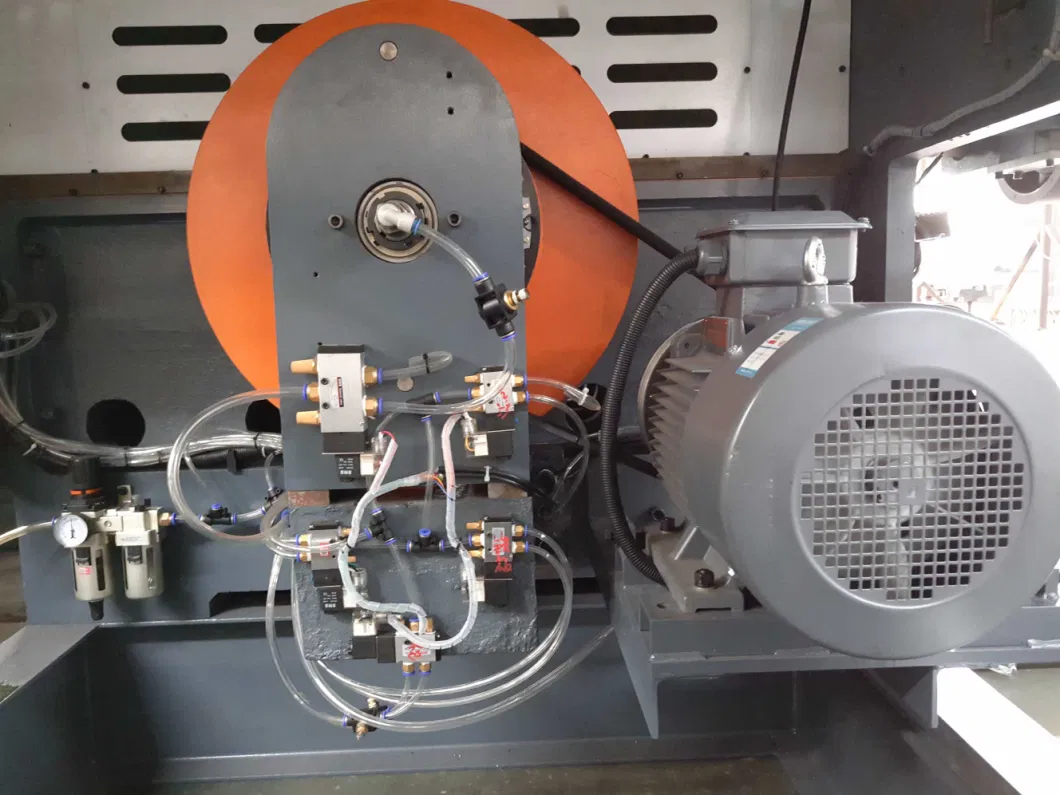

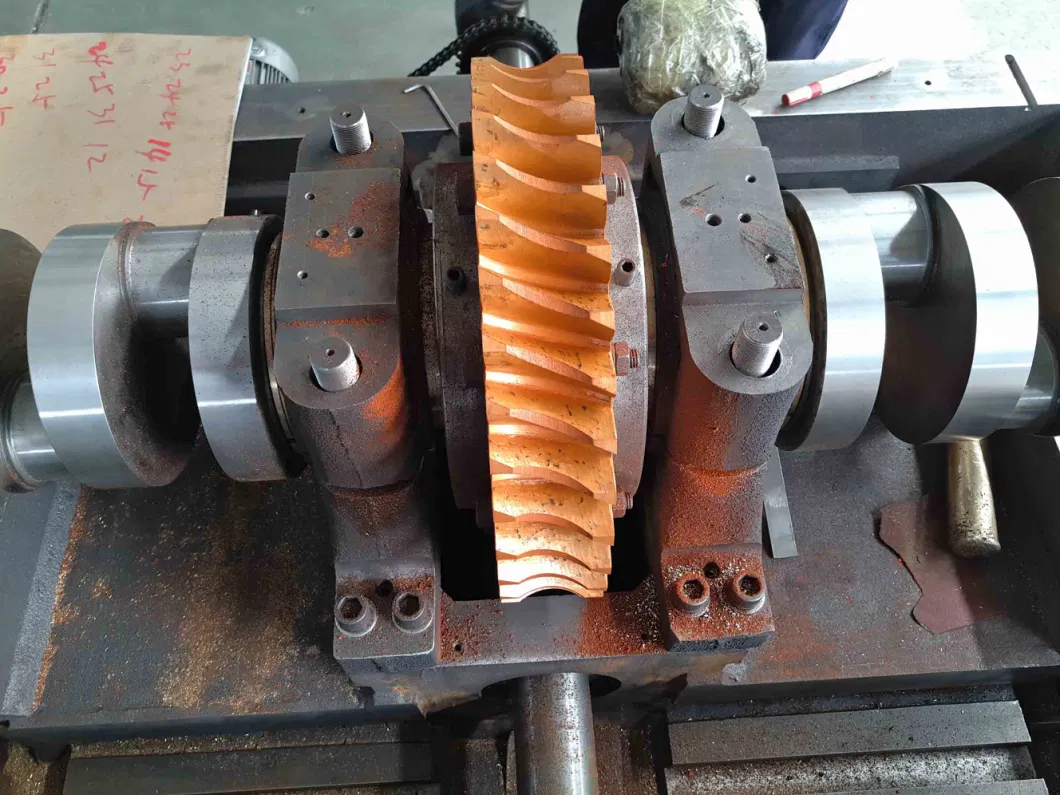

The 11 KW Siemens Motor together with the pneumatic clutch, worm shaft and worm gear forms a moving set to ensure stable pressure out put of not less than 300 tons.

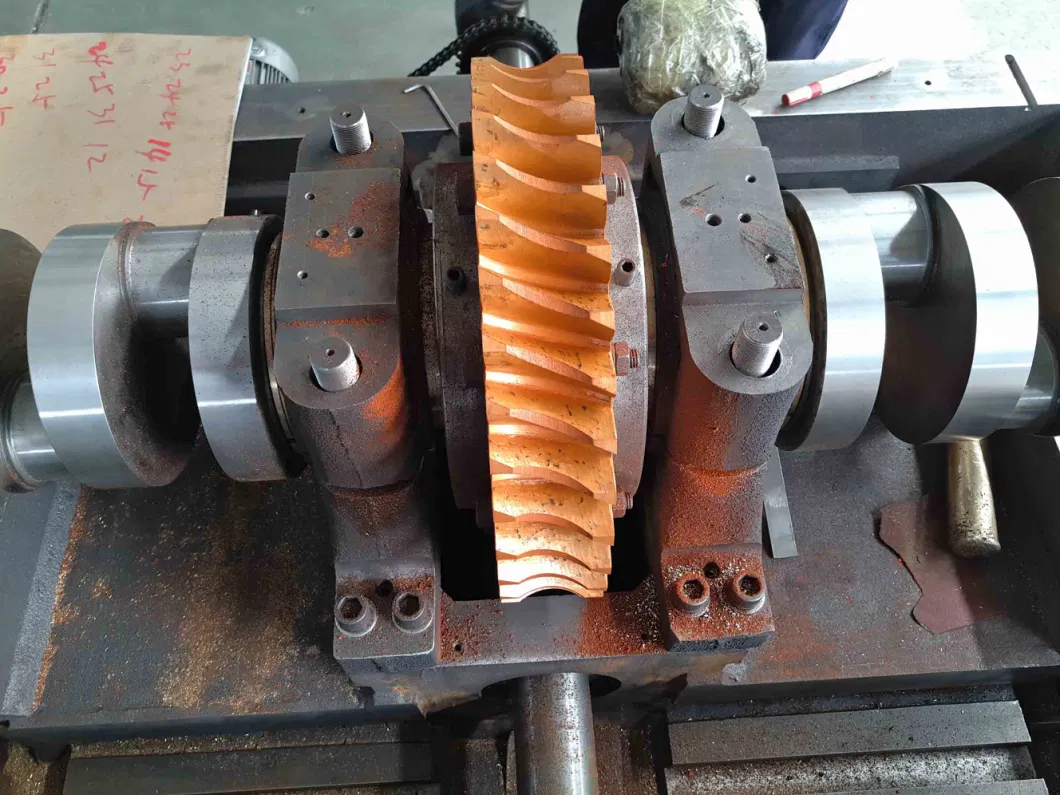

T h e material for the worm shaft is 40Cr with quenching treatment and gear hardness HRC 45-50. the material for the worm is copper alloy - ZQAL9-4.

The bearing that is used is SKF. The bush is copper alloy ZQSn6-6-3 .

T he pendulum is made of high quality ductile iron. The pendulum axis is done by induction harden with surface hardness HRC 43-48. The width of the pendulum is 250mm and diameter of pendulum shaft 70 mm - completely follow the specification of 1080 type automatic die-cutting and creasing machine. Compared with automatic die-cutting and creasing machine which is used for cardboard die-cutting, this type of semi-automatic die-cutting and creasing machine is mainly used for corrugated board which needs less pressure for die-cutting, in this case quite some producers have made smaller width on the pendulum and smaller diameter on the pendulum shaft. We keep wider pendulum and bigger diameter on its shaft to make our machine last for a longer life.

The die-cutting plate uses 7 mm 75 Crl plate which has more hardness and life span than the manganese plate.

It adopts 3-cam intermittent positioning device to ensure the boarding conveying accurate and stable.

The machine uses gripper bar type with 12A long joints chain which is less in weight and less shock to the intermittent device under the precondition to ensure the strength of the chain. The brand of the chain is Renold U.K with high precise and quality. .

T he Gripper bar adopts aviation aluminum with three bridge type- light in weight and high in strength.

The electrical parts are designed and assembled according to the European CE standard and uses world wide known brand products.

There are two ways for the fixation of the die - either by bolt or clippers which are subject to customer ' s advice.

The chase locking is pneumatic which is simple, convenient and reliable.

Generally the producers will install sensors on this part to stop the machine when the paper is fed abnormally to the front lay. However, when the machine is running at the high speed, the inertia will bring the machine to run for a while to make the front lay to its highest point and then also damage the front lay and the gripper bar.

Our special design is that when the abnormal board feeding happens and being detected, the front lay can never reaches to its highest point which makes free from front lay and gripper bar damages because of abnormal paper feeding.

As it is our special design, so there is no picture to be shown here.

The pre - loading device is pneumatic driven. When one paper size is set, when you do other pile of pre - loading, there is no bother of you to reset the pre - loading device, you can just press the button and the machine will do for you.

T he lifting step unit is also pneumatic to facilitate the conveying of the paper pile.

Our machine uses an additional dance roller feeding system whose board feeding time can be extend to 0.6 second. Together with the conveying parts it makes an easier work of the operator and faster in efficiency of the machine.

For example: If an operator operates the direct feeding semi-automatic die-cutting machine at 3300 sheets per hour, he can easily operate our machine at 3700 - 4000 sheets per hour.

- Specifications:

| Model | Unit | MY1200 | MY1300 | MY1500 |

| Max. Paper Size | mm | 1200*780 | 1300*960 | 1500X1100 |

| Min. Paper Size | mm | 350*350 | 400*400 | 500X400 |

| Max. Die-cutting Size | mm | 1180*760 | 1280*940 | 1480X1080 |

| Max. Speed | sh/h | 0-5000 | 0-4600 | 0-4000 |

| Max. Working Pressure | T | 300 | 300 | 300 |

| Max. Paper Thickness | mm | 1-7 | 1-7 | 1-7 |

| Die-cutting Precision | mm | ±0.5 | ±0.5 | ±0.5 |

| Total Power | KW | 15 | 15 | 19 |

| Total Weight | KG | 11500 | 13000 | 16000 |

| Overall Dimension | mm | 5150*4000*2145 | 5670*4100*2145 | 6100*4600*2205 |

- Features of the machine:

- The scissors type cut structure makes the cutting platform movement like a scissor, it will realize a full and easier cut.

- Main worm gear uses alloy copper material, after the experienced operator's manual scraping treatment and strict standard testing, it can ensures the driving parts 10 years life.

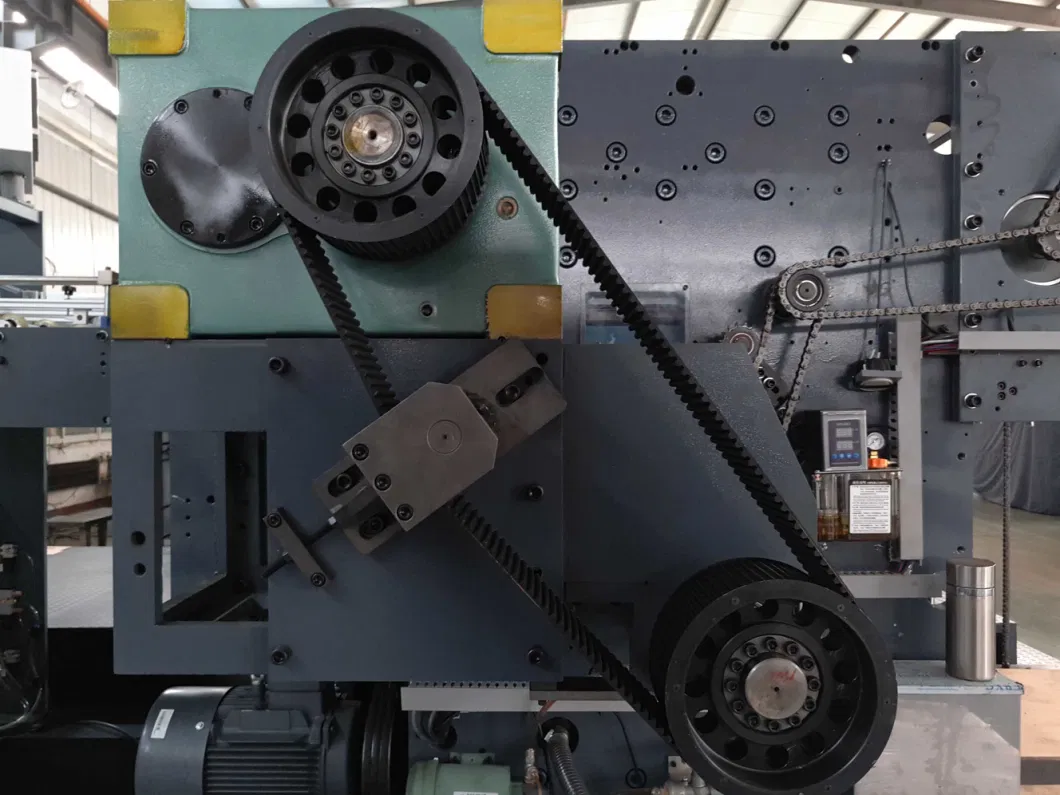

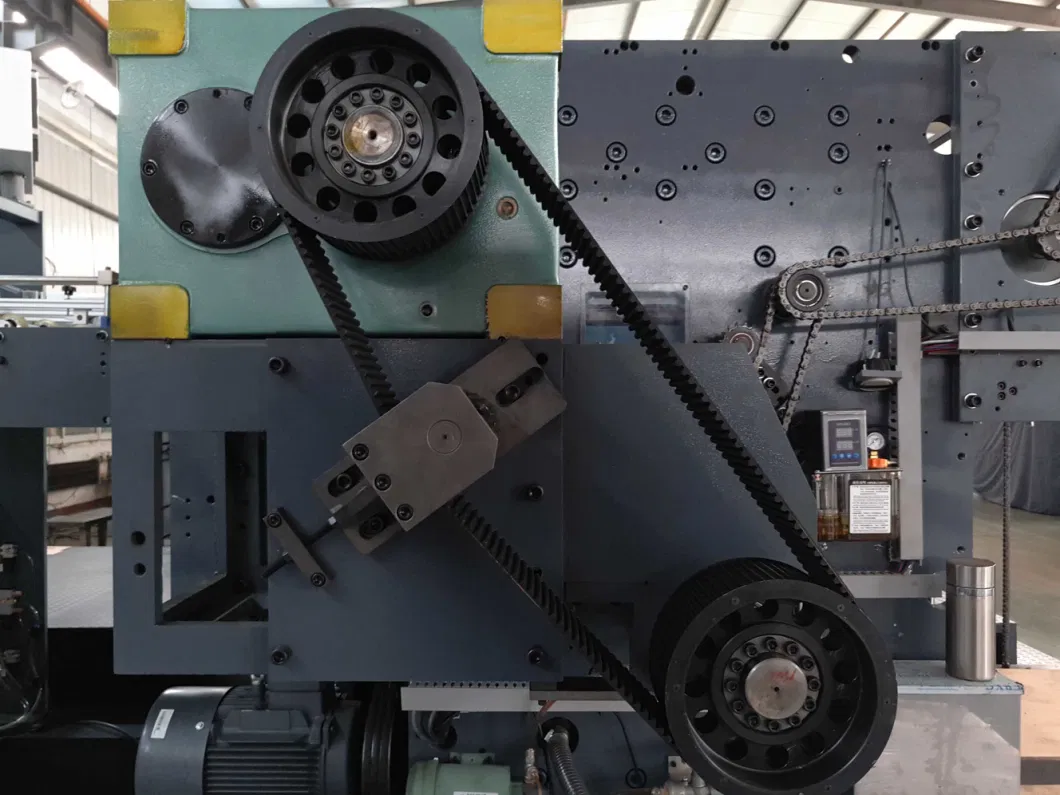

- The main chains adopt imported British Renold brand, the differences of 10 chains are less than 0.2mm.

- The connect between gear box and driving shaft adopts sleeve and pin structure ensuring a strong connection.

- Speed:

- Safety:

Besides the sensors at die-cutting part, there are sensor or approach switches at window part to make the whole machine at monitoring status to ensure its safety.

- Operation convenience:

- Main Structures and Key Material Used

- Four Main Big Parts:

- Main Drive:

The 11 KW Siemens Motor together with the pneumatic clutch, worm shaft and worm gear forms a moving set to ensure stable pressure out put of not less than 300 tons.

T h e material for the worm shaft is 40Cr with quenching treatment and gear hardness HRC 45-50. the material for the worm is copper alloy - ZQAL9-4.

The bearing that is used is SKF. The bush is copper alloy ZQSn6-6-3 .

- Die-cutting and Creasing Part:

T he pendulum is made of high quality ductile iron. The pendulum axis is done by induction harden with surface hardness HRC 43-48. The width of the pendulum is 250mm and diameter of pendulum shaft 70 mm - completely follow the specification of 1080 type automatic die-cutting and creasing machine. Compared with automatic die-cutting and creasing machine which is used for cardboard die-cutting, this type of semi-automatic die-cutting and creasing machine is mainly used for corrugated board which needs less pressure for die-cutting, in this case quite some producers have made smaller width on the pendulum and smaller diameter on the pendulum shaft. We keep wider pendulum and bigger diameter on its shaft to make our machine last for a longer life.

The die-cutting plate uses 7 mm 75 Crl plate which has more hardness and life span than the manganese plate.

- Board Conveying:

It adopts 3-cam intermittent positioning device to ensure the boarding conveying accurate and stable.

The machine uses gripper bar type with 12A long joints chain which is less in weight and less shock to the intermittent device under the precondition to ensure the strength of the chain. The brand of the chain is Renold U.K with high precise and quality. .

T he Gripper bar adopts aviation aluminum with three bridge type- light in weight and high in strength.

- Electric Part

The electrical parts are designed and assembled according to the European CE standard and uses world wide known brand products.

- Installation of Die

There are two ways for the fixation of the die - either by bolt or clippers which are subject to customer ' s advice.

The chase locking is pneumatic which is simple, convenient and reliable.

- Special Characters of Our Machine:

- Clever And Special Front Lay Design:

Generally the producers will install sensors on this part to stop the machine when the paper is fed abnormally to the front lay. However, when the machine is running at the high speed, the inertia will bring the machine to run for a while to make the front lay to its highest point and then also damage the front lay and the gripper bar.

Our special design is that when the abnormal board feeding happens and being detected, the front lay can never reaches to its highest point which makes free from front lay and gripper bar damages because of abnormal paper feeding.

As it is our special design, so there is no picture to be shown here.

- Optional Delivery Platform:

- Pneumatic Pre-loading and Lifting Step Unit:

The pre - loading device is pneumatic driven. When one paper size is set, when you do other pile of pre - loading, there is no bother of you to reset the pre - loading device, you can just press the button and the machine will do for you.

T he lifting step unit is also pneumatic to facilitate the conveying of the paper pile.

- Dancing Roller Feeding:

Our machine uses an additional dance roller feeding system whose board feeding time can be extend to 0.6 second. Together with the conveying parts it makes an easier work of the operator and faster in efficiency of the machine.

For example: If an operator operates the direct feeding semi-automatic die-cutting machine at 3300 sheets per hour, he can easily operate our machine at 3700 - 4000 sheets per hour.

- Configurations:

| Name | Brand and Origin | Remarks |

| Bearing | SKF Swiss | Key part |

| IKO Japan or Harbin, China | Not key part | |

| Chain | Renold U.K; | Main Chain ( Discrepancy of less than 0.2 mm for per 10 chains of machine chain length) |

| CHOHO Japan | Other Chain are Choho Japan | |

| Relay | Omron Japan | |

| Contactor, buttons | TELEMECANIQUE France | |

| Photo Electric Switch | Fotek Taiwan | |

| Stabilizer | MEANWELL Taiwan | |

| Variator | Delta Taiwan | |

| Main Motor | Siemens | Joint Venture |

| PLC | Delta, Taiwan | |

| Man-machine Interface | Delta | |

| Pneumatic Parts | Sunrise, Taiwan | |

| Rotary Joints | SMC Japan | |

| Motor at feeding and delivery | CPG Taiwan |